AI Vision Inspection Like Human Eyes

We build vision inspection systems that observe, understand, and adapt like humans – with the reliability and consistency of robots.

Industry Challenges

Manual visual inspection is tedious and inconsistent. Our AI-powered solution eliminates human error while maintaining the adaptability of human judgment.

Cost Of Defects

Scrap Rates in injection molding can reach up to 10%, cutting directly into yield

Defects = wasted material, rework, late deliveries, reputation loss.

The Hidden Cost of Downtime

Downtime can erode ~11% of annual revenues in large manufacturers

Unplanned downtime cost manufacturers an average of $260,000/hour

Manual inspections often fail to prevent stoppages

Traditional Inspection Falls Short

Manual checks are slow, inconsistent, and prone to fatigue.

Tiny defects are often missed.

Leads to costly rework, rejected shipments, and downtime.

Value Proposition

Value Proposition

Surface Defect Detection

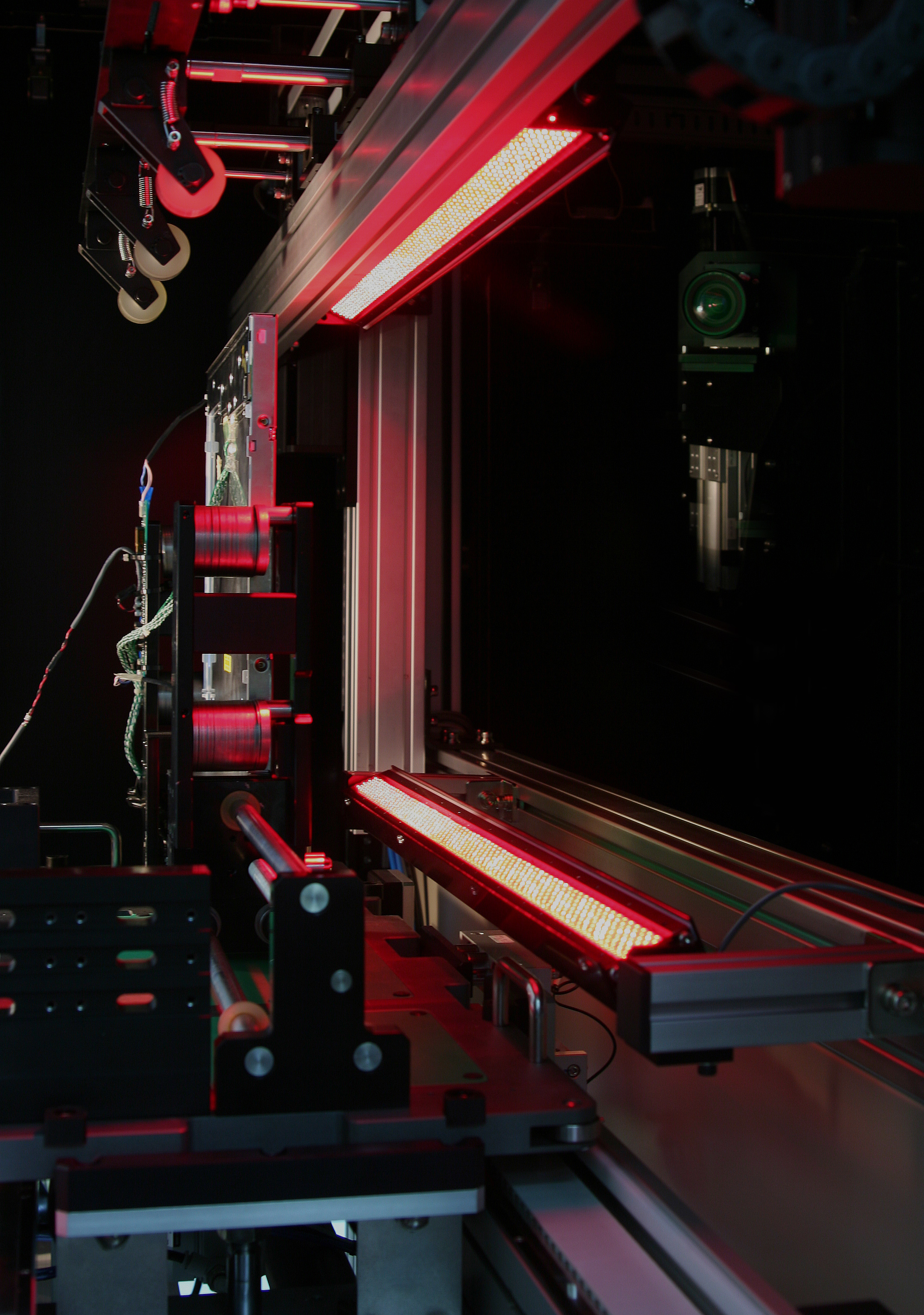

Multi-View System

Proprietary inter-camera calibration mimics human inspector manipulation

Precision Detection

Detects defects as small as 50μm on top, bottom, and side surfaces

Shape Independent

Supports diverse parts - cutting inserts, round injection-molded components

Material Robust

High accuracy even for transparent or translucent parts

NSIX Vision Keys Software

The platform powering the pi360 system, delivering high performance and adaptability through:

Parallelized Architecture

Asynchronous image capture and multi-detector execution for fast and efficient inspection.

Distributed Computing

Scale processing power through parallel computing to run more detectors in less time.

3D Visualization

Real-time 3D viewer for test parts and detection results — see insights as they happen.

End-to-end Learning Tool Suite

Integrated TRaining-Inspection-Labeling software suite – blaze the TRAIL from data to deployment

NSIX Has An AI Vision Solution For Your Industry

Flexible Inspection for Injection Molding

Consistent Performance On Transparent Materials

Inspect transparent and translucent parts with virtually no loss in detection accuracy or increase in false detections.

Robust Detection Of Variable Defects

Reliably detect defects with high variability or unclear visual definition.

Enhanced Reliability Through Multi-camera Calibration

Proprietary inter-camera calibration ensures consistent defect detection across views, significantly reducing false positives.

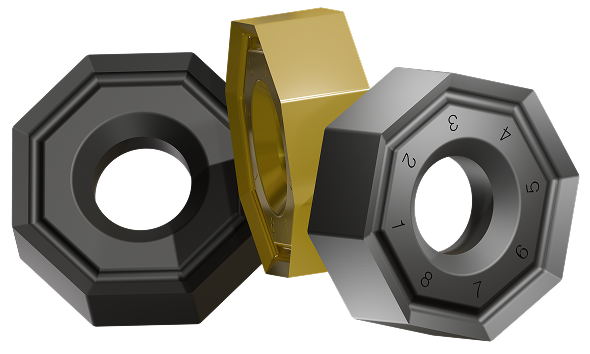

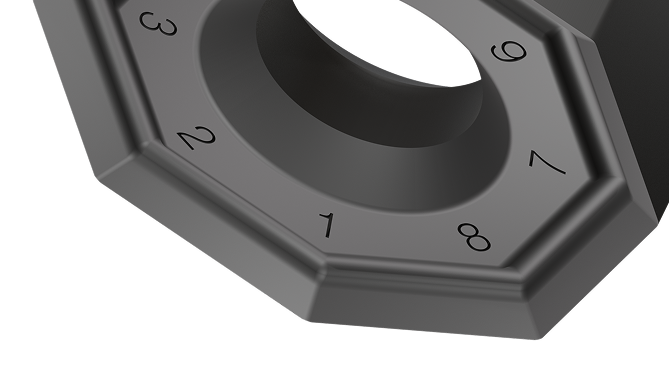

Advancing Cutting Inserts Inspection

Comprehensive Multi-angle Inspection

Comprehensive multi-angle inspection: Proprietary optical design enables full 360° inspection of each insert, including top, side, and bottom surfaces.

Minimal Camera Setup

Achieves complete visual coverage with fewer cameras than competing systems, reducing cost and complexity.

High Accuracy For Complex Geometries

Precisely captures side and bottom surfaces even on inserts with positive angles that are difficult to view manually.

Other Industries

For more than 20 years, we’ve been creating innovative mechanical, optical, electrical, and software solutions for industry leaders in medical technology, electronics, automotive, irrigation, aerospace, and beyond.

Our Customers

"Cost effective and of consistently high quality"

We rely on NSIX Vision for our Robotics R&D projects with applications of bin picking and machine learning. NSIX delivers robotic cells equipped with vision measurement modules for accuracy verification. Their systems are cost effective and of consistently high quality; they passed rigorous certification with compliments from the external inspection.

"Operates smoothly in production and is easy to use for the operators"

NSIX Vision delivered the vision system for 3D navigation of our palletizing robots. The system operates smoothly in production and is easy to use for the operators. NSIX’s automated calibration is beneficial for the maintenance personnel so that there’s no need in support or service calls.

"Real world vision experts every step of the way"

NSIX Vision delivered a vision system for a pick-and-place robotic packaging solution for a major customer of ours. My team felt that we are supported by real world vision experts every step of the way - from developing initial simulations to having a reliable working production system.

The system they delivered works with a variety of products and packaging bins with easy switching between production recipes, all the while meeting challenging cycle times. NSIX Vision Keys software and their 3D cameras integrated easily with the robot and customer's production system, thanks to their built-in PLC interfaces.

I'm particularly impressed with the intelligent algorithm for 3D bin placement optimization. We are confident with NSIX's services and look forward to having more projects together!

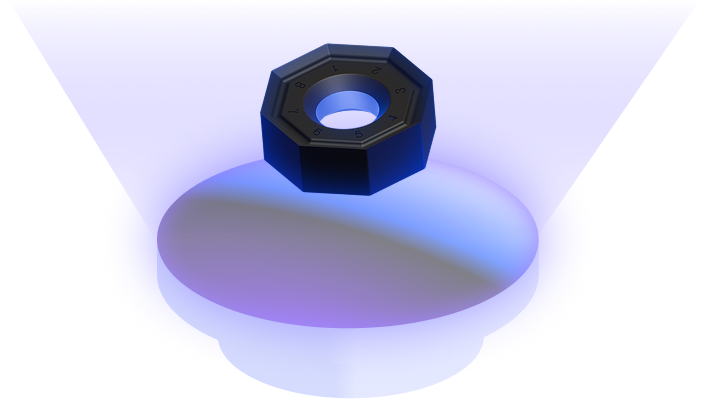

Example Configuration

Injection molding parts inspection setup with comprehensive defect detection

System Specifications

ask about customization for smaller defect size

real-time 3D viewer,

Vision TRAIL AI learning suite

Key Benefits

Uniform product quality with automated, repeatable inspection

Reduced Dependence on Manual Inspection

Decrease the number of human inspectors without compromising quality.

Human operators take supervisory roles

Less stressful, more impactful work

Minimized false rejections

Defect classification and sizing

Ready to Transform Your Inspection Process?

Join the manufacturing companies already using NSIX Vision's pi360 system to improve quality and reduce inspection costs.