NSIX Has An AI Vision Solution For Your Industry

Medical

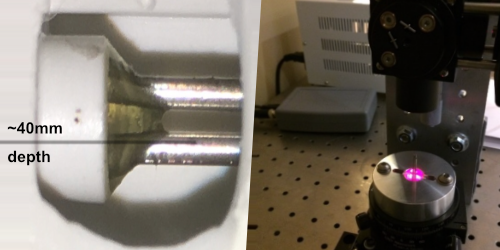

Measuring sealant level deep inside narrow cylinder (under 10mm diameter)

Flat Panel Displays

Multi-camera AOI - design and PM for motion system, cameras, optics and software

Semiconductors

Vision inspection of bonding machines capillaries (1 μm inspection tolerance)

Robotic Cells

Complete ISO 10218-1:2011 certified robotic cells for bin picking and machine learning

Food / Agriculture: Sweet Potato Automation

Automotive: Pick N Place Palletizing

Flexible Inspection for Injection Molding

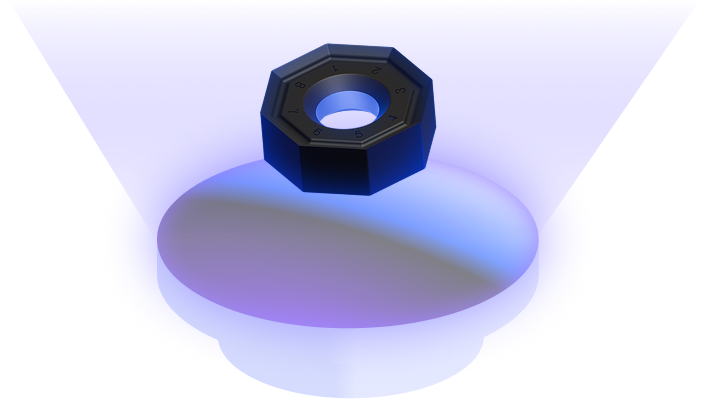

Consistent Performance On Transparent Materials

Inspect transparent and translucent parts with virtually no loss in detection accuracy or increase in false detections.

Robust Detection Of Variable Defects

Reliably detect defects with high variability or unclear visual definition.

Enhanced Reliability Through Multi-camera Calibration

Proprietary inter-camera calibration ensures consistent defect detection across views, significantly reducing false positives.

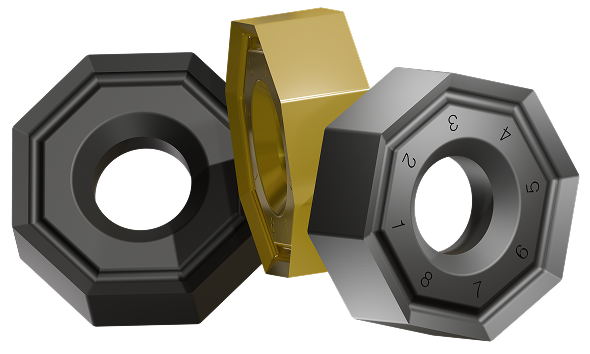

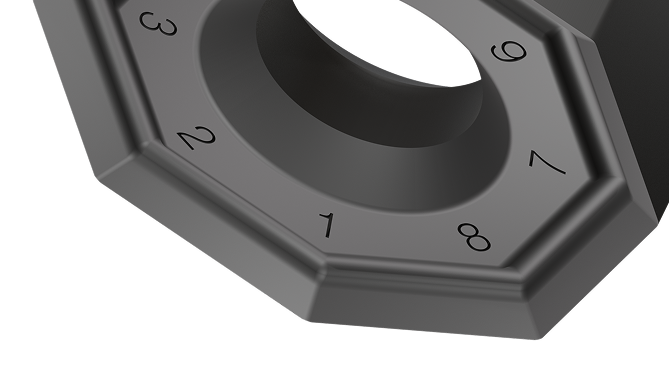

Advancing Cutting Inserts Inspection

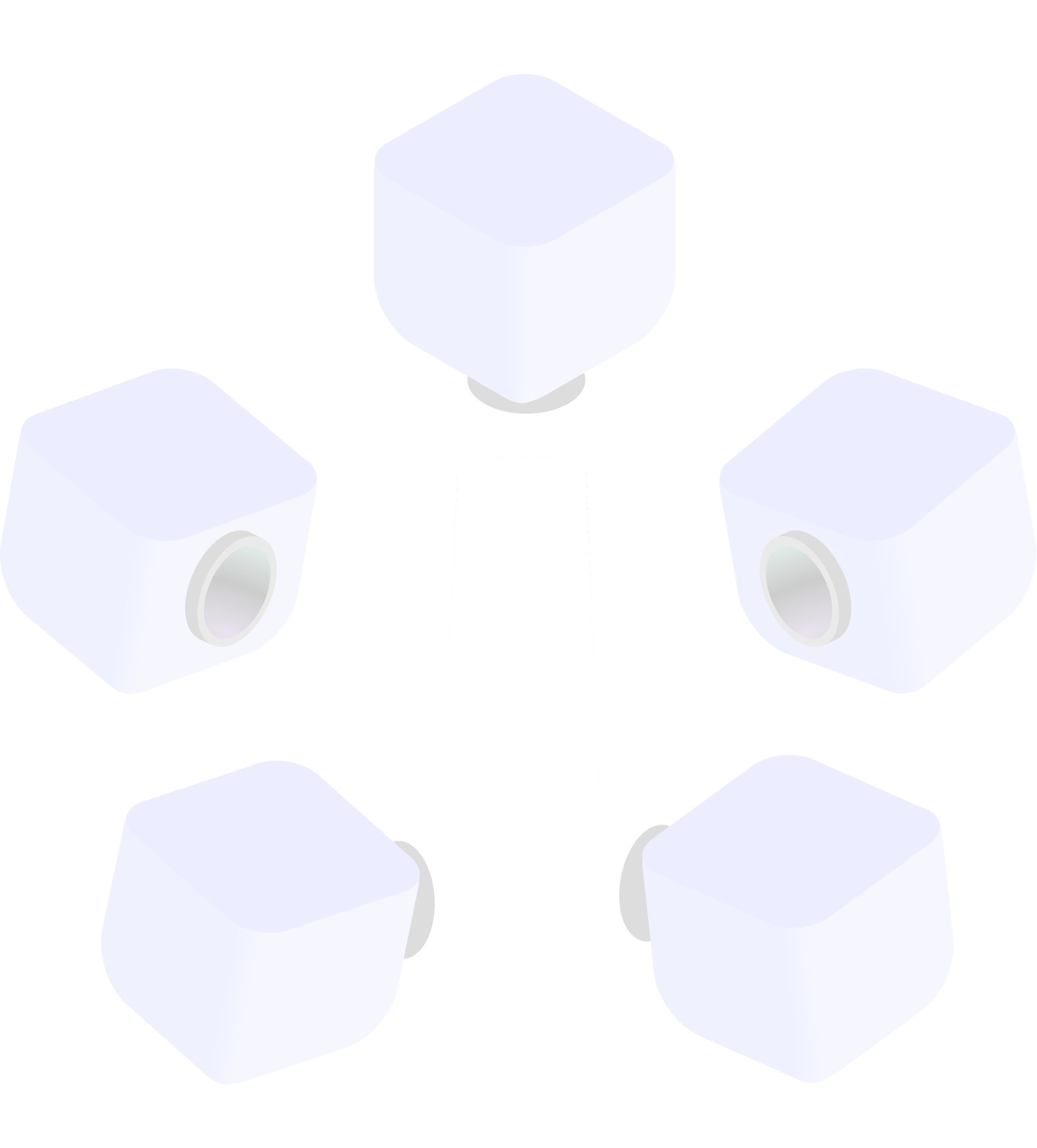

Comprehensive Multi-angle Inspection

Comprehensive multi-angle inspection: Proprietary optical design enables full 360° inspection of each insert, including top, side, and bottom surfaces.

Minimal Camera Setup

Achieves complete visual coverage with fewer cameras than competing systems, reducing cost and complexity.

High Accuracy For Complex Geometries

Precisely captures side and bottom surfaces even on inserts with positive angles that are difficult to view manually.